High-Pressure-Injector for conveying and dispersion of gas-solids-mixtures

One of the frequent tasks in the process technology is to put and disperse solids in finely and optimal form into the reaction space. In the area of gas cleaning for example there is a demand to disperse sorbents in optimal concentration into exhaust gas ducts or combustors. To satisfy this demand there is necessary a particular dispersion- and penetration-depth. The recently developed High-Pressure-Injector offers the solution for this problem and in addition to that it is also able to intake sorbences over a short distance (max. app. 10 m). As a result, in case of smaller plants and shorter ducts, there is no necessity to applicate expensive pneumatic conveying systems.

Basically it is a particular construction form of the well-known Coanda-Ejector. Transported good enters in the middle flowing through the central tube, which has no narrowing parts and prevents so any blockage. The coaxially outtreading air from a narrow opening wraps around the solid or the end section of the injector and mixes itself with the sorbence. Because of the high velocity at the opening and the shear force there can be achieve a very good dispersion in the air jet. The swelling angle of the air-solid-mixture can be influenced by the injector contour.

There are possible common loads of app. 0,5 to 3 kg of solids per 1 kg air. The air is supplied from normally existing air-pressure-net with 6-7 bar overpressure or from a mobile air-pressure-generator. The quantity of air or gas depends on the quantity of solids to be dispersed. The High-Pressure-Injector can handle the air throughput of 10-30 m3/h for example. This way can be realized conveying-quantities of 5-90 kg/h. A corresponding list for smaller and bigger conveying-quantities is on preparation.

The conveying air which can be applicated must be dry (by a refrigeration drier as a minimum requirement), particle- and oilfree. This can be assured by a control unit. The air quantity and – pressure are controlled by a series flowmeter and monometer.

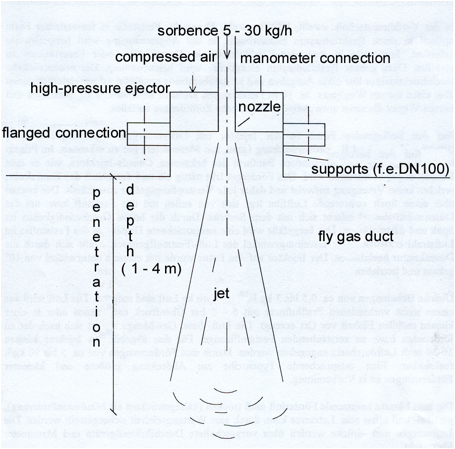

The High-Pressure-Injector can be easily fastend on the pipe flange and connected with the reaction space (see sketch). The quantity air and the quality of dispersion can be influenced by adjusting the central tube.

Summarising, it can be said that the High-Pressure-Injector is able to satisfy the requirements of:

- Fine dispersion

- Definite penetration-depth

- Conveying and pneumatic intake over short distance

In simple, reliable way, saving place and energy consumption and can be easily adapted to the particular requirements at the location.

Diagram of the installation unit of the High Pressure Injector

Schneider: „Use of Gas-Solid-Ejectors as Inward Transfer Units for Pneumatic Conveying of Bulk Solids“, Schüttgut 2 (1996)